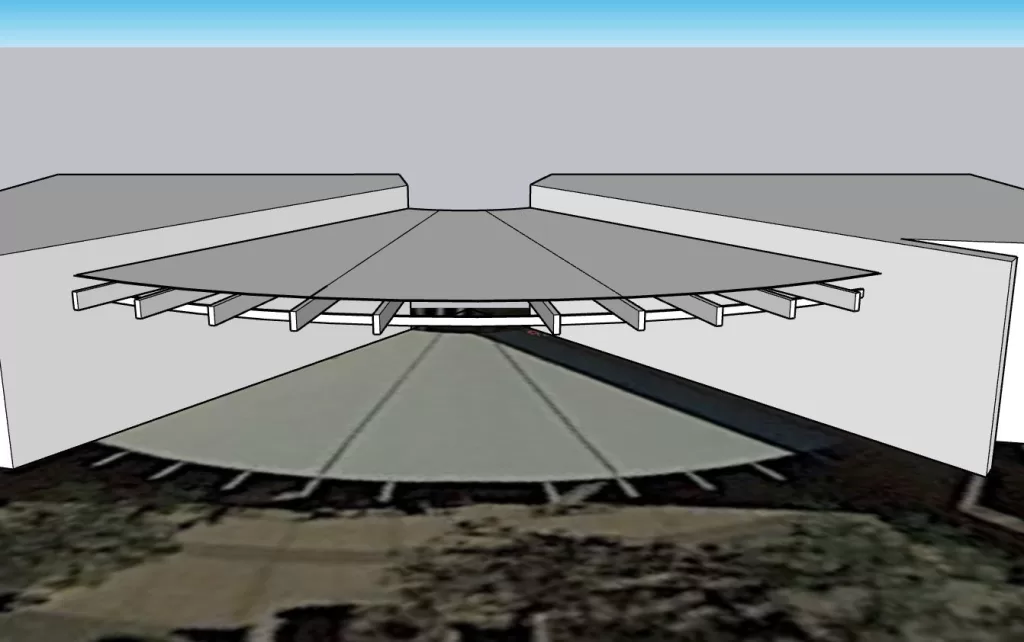

The We-Ko-Pa Golf Club in Fort McDowell, Arizona contacted us to replace three prominent triangular-shaped vinyl lace panels. The three lace panels are approximately 62′ x 31′ x 7′ each, necessitating the use of our 3D Coordinate Laser.

Each panel used heavy-duty grommets on the perimeter. A diamond braded rope laces through the grommets to a lace rail to tension the panels. The two outer lace panels have Kedar sewn on the building side. Allowing them to slide into the existing Kedar track that is mounted along the building. The three lace panels are situated approximately 25 feet above a restaurant patio.

3D Coordinate Laser Measurment Process

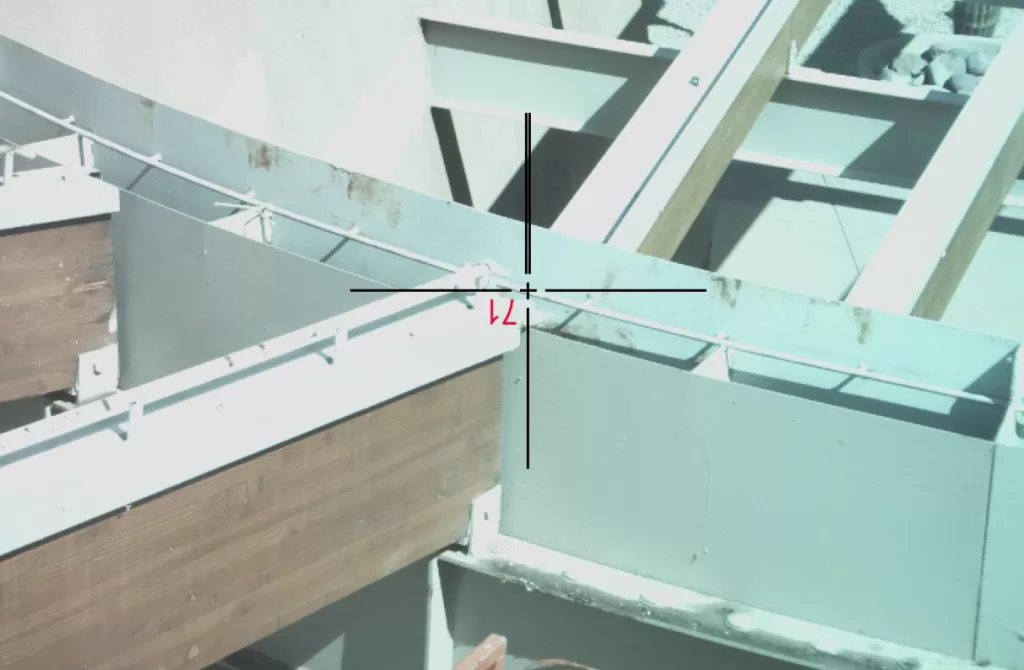

We utilized our 3D Coordinate Laser to obtain precise measurements for this project for a few reasons. The panels are positioned directly above a gutter system integrated into the lace panel structure, the multiple long-spanned ribs, and overall size of the structure.

Each outer panel had three supporting ribs that were connected to three structural supports, while the center panel had 2 ribs connecting to 2 center structural supports.

Utilizing our 3D coordinate laser ensured precise measurements for the edge of each canopy and each canopy rib.

The laser could not see a few necessary measurements from the ground. We brainstormed on a quick solution measure these points and came up with a jig that held that laser upside down.

We mounted the jig to the scissor lift and raised the scissor lift about 3’ above the structure to get all the measurements we needed.

Often you must think outside the box and push your tools to get the best outcome, and this was a great example.

Using the laser to measure all three lace panels significantly reduced labor and equipment costs.

We were able to easily design the new vinyl panels due to the laser scan process. Subsequently, we upload the measurements to CAD and/or SketchUp to generate a for the customer

This process not only creates a visual model for the customer but creates a dimensioned drawing we use to create our new lace panels. We can create an accurate scale model of almost any project due to the laser’s precise measurements.

Benefits of a 3D Coordinate Laser

The laser as our most versatile tool for measurements and accurate layouts.

Our laser can scan almost any surface where there is not an obstruction in the way reducing errors. We can measure projects in more than half the time.

The laser not only ensures rapid data collection, but the laser can take pictures of every single dimension point you take.

This is extremely beneficial for a project that requires time to materialize and maintain precise dimensions with annotations.

The laser also can be utilized as a layout tool as well. By programming the laser with a set of measurements, it can accurately mark points for installation on almost any surface. In short, the 3D Coordinate Laser is the superior method for measuring projects today.